The Complete Guide to Modern Name Badge Manufacturing: From Eco-Friendly Materials to Solid Metal Excellence

Discover how advanced manufacturing techniques create perfect name badges for every industry, budget, and sustainability goal

15+ Material Options

100% USA Made

3-5 Day Production

Modern name badge manufacturing has evolved far beyond simple plastic tags. Today's advanced production techniques create everything from sustainable bamboo badges to premium solid metal designs, each tailored to specific industry needs and brand identities. Whether you prioritize environmental responsibility, executive elegance, or budget efficiency, understanding the manufacturing process helps you choose the perfect identification solution.

The Evolution of Name Badge Manufacturing

Name badge manufacturing has transformed dramatically over the past decade. What once required expensive tooling and massive minimum orders can now be produced efficiently in any quantity, with personalization options that would have been impossible just years ago.

Modern Manufacturing Advantages

- Digital precision: Computer-controlled cutting and engraving for perfect consistency

- Material versatility: From recycled plastics to exotic hardwoods

- Quick turnaround: Advanced equipment enables 3-5 day production

- No minimums: Efficient processes make single badges cost-effective

- Customization flexibility: Unlimited design possibilities without tooling costs

- Quality consistency: Automated processes ensure every badge meets specifications

This manufacturing evolution means organizations of any size can access professional identification solutions that perfectly match their brand identity and functional requirements.

Eco-Friendly Name Badge Manufacturing

Environmental responsibility drives innovation in sustainable name badge production. Modern eco-friendly badges prove that sustainability doesn't require sacrificing quality or professional appearance.

Bamboo Name Badges

Rapidly renewable bamboo offers natural beauty with minimal environmental impact. Each badge showcases unique wood grain patterns while supporting sustainable forestry practices.

- Grows 3-4 feet daily, harvests in 3-5 years

- No pesticides or fertilizers needed

- Naturally antibacterial surface

- Laser engraving creates permanent marking

- Biodegradable at end of life

Carbon Negative Production

Explore Bamboo Options

Recycled Plastic Badges

Post-consumer recycled plastics transform waste into professional identification. These badges match traditional plastic quality while diverting materials from landfills.

- 100% post-consumer recycled content available

- Same durability as virgin plastic

- Full color printing capabilities

- Recyclable after use

- Reduces petroleum dependency

85% Less Energy Than Virgin Plastic

Cork Name Badges

Harvested bark creates unique, sustainable badges without harming trees. Cork's natural properties provide excellent durability and distinctive appearance.

- Trees regenerate bark every 9 years

- Naturally water-resistant

- Lightweight and comfortable

- Unique texture and appearance

- Completely biodegradable

Zero Tree Mortality

Sustainable Manufacturing Processes

- Solar-powered facilities: Renewable energy reduces production carbon footprint

- Water-based adhesives: Eliminates harmful VOC emissions

- Waste reduction programs: Material scraps recycled or composted

- Local sourcing: Reduced transportation emissions

- Minimal packaging: Recycled and recyclable shipping materials

Premium Plastic Badge Manufacturing

Plastic remains the most versatile and popular name badge material, offering unlimited customization options at accessible price points. Modern plastic manufacturing techniques deliver exceptional quality and durability.

Plastic Manufacturing Methods

Digital UV Printing

High-resolution full-color printing with UV-cured inks provides vibrant, scratch-resistant graphics that maintain appearance for years.

- 1440 DPI resolution for photo-quality images

- Unlimited color options

- Instant curing prevents smudging

- Chemical and abrasion resistant

Laser Engraving

Precision laser technology creates permanent markings by altering the plastic substrate, ensuring text and graphics never fade or wear off.

- Permanent marking won't fade

- Fine detail capability

- Two-tone contrast effects

- No inks or chemicals required

Sublimation Printing

Heat-transfer process embeds dyes directly into plastic surface, creating vivid colors that become part of the badge material.

- Photographic quality reproduction

- Colors won't chip or peel

- Smooth, professional finish

- Ideal for complex graphics

Plastic Material Options

- Standard ABS: Durable, lightweight, perfect for everyday use

- Premium acrylic: Crystal-clear appearance with superior scratch resistance

- Metallic finishes: Gold, silver, bronze effects without metal weight

- Translucent options: Modern appearance with depth effects

- Textured surfaces: Matte, brushed, or patterned finishes

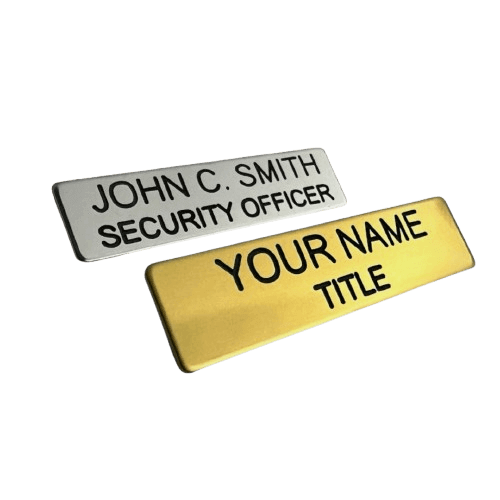

Solid Metal Badge Manufacturing Excellence

Metal badges represent the pinnacle of professional identification, conveying authority, permanence, and prestige. Advanced metalworking techniques create badges that last decades while maintaining pristine appearance.

Metal Manufacturing Techniques

- Precision die-cutting: Computer-controlled cutting for perfect dimensions

- Deep etching: Chemical or laser etching creates recessed text and graphics

- Diamond drag engraving: Creates elegant grooved text with metallic shine

- Color filling: Enamel or epoxy adds color accents to engraved areas

- Edge finishing: Beveled, rounded, or straight edges for comfort and appearance

- Surface treatments: Brushing, polishing, or texturing for desired finish

Specialty and Decorative Badge Manufacturing

Beyond traditional materials, specialty manufacturing techniques create badges that make memorable impressions and reinforce unique brand identities.

Rhinestone and Bling Badges

Perfect for fashion, beauty, entertainment, and luxury retail environments where glamour enhances brand image.

- Genuine crystal options: Swarovski elements for maximum sparkle

- Secure stone setting: Industrial adhesives prevent stone loss

- Custom patterns: Logos, borders, or full coverage designs

- Color variety: Clear, colored, or AB (aurora borealis) finishes

- Mixed media: Combine with metal or plastic bases

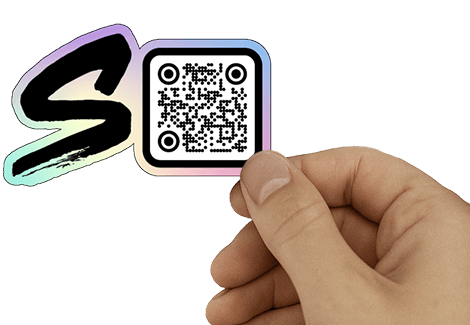

Holographic and Special Effects

Advanced materials create eye-catching visual effects that change with viewing angle, perfect for events, entertainment, and security applications.

- 3D holographic films: Depth effects without actual dimension

- Color-shifting materials: Changes appearance with movement

- Reflective elements: Mirror finishes and metallic effects

- UV-reactive inks: Hidden elements visible under blacklight

- Thermochromic materials: Color changes with temperature

Multi-Layer Construction

Dimensional badges combine materials and layers for sophisticated appearance and enhanced durability.

- Raised lettering: 3D text stands proud of background

- Recessed elements: Sunken areas create depth

- Mixed materials: Combine metal, plastic, and wood

- Window effects: Transparent layers over graphics

- Floating elements: Components appear suspended

Smart Badge Manufacturing and Technology Integration

Modern manufacturing incorporates technology for enhanced functionality beyond simple identification.

RFID and NFC Integration

Embedded chips enable access control, time tracking, and contactless interactions while maintaining traditional badge appearance.

- Invisible integration: Chips hidden within badge structure

- Dual functionality: Visual ID plus electronic capabilities

- Encryption options: Secure data storage and transmission

- Multi-frequency support: Compatible with various systems

- Durability tested: Chips survive daily wear and cleaning

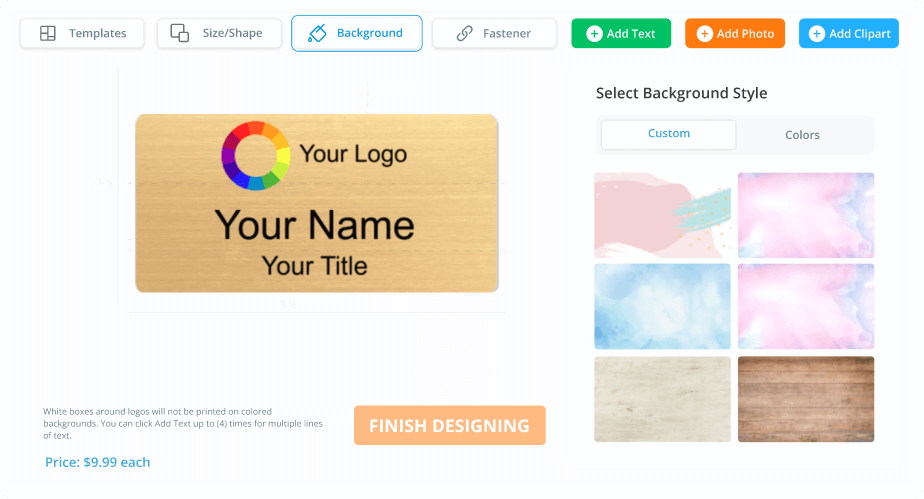

QR Code and Digital Integration

Printed codes connect physical badges to digital resources, enabling dynamic content and tracking capabilities.

- Dynamic QR codes: Update destination without reprinting

- vCard integration: Instant contact sharing

- Analytics tracking: Monitor badge scans and interactions

- Multi-language support: Different content by scan location

- Social media linking: Connect to professional profiles

Manufacturing Quality Control and Standards

Professional badge manufacturing requires rigorous quality control to ensure every badge meets specifications and durability requirements.

Quality Assurance Process

- Material inspection: Verify raw materials meet specifications

- Color calibration: Match brand colors precisely

- Dimensional accuracy: Measure against specifications

- Print quality verification: Check resolution and registration

- Durability testing: Simulate wear conditions

- Final inspection: Individual badge review before shipping

Industry Certifications and Standards

- ISO 9001: Quality management system certification

- ANSI standards: Size and safety specifications

- RoHS compliance: Restriction of hazardous substances

- CPSIA compliance: Consumer Product Safety requirements

- ADA compliance: Accessibility considerations for text size

Bulk Ordering and Enterprise Solutions

Organizations requiring large-scale badge deployments benefit from our streamlined bulk ordering process and dedicated account management. Whether you need 50 badges or 5,000, our manufacturing capacity scales to meet your timeline and budget.

Volume Pricing Tiers

| Quantity |

Discount |

Per Badge Savings |

Lead Time |

| 25-49 badges |

10% off |

$0.90-2.50 |

3-5 days |

| 50-99 badges |

15% off |

$1.35-3.75 |

4-6 days |

| 100-499 badges |

20% off |

$1.80-5.00 |

5-7 days |

| 500+ badges |

30% off |

$2.70-7.50 |

7-10 days |

Multi-Location Order Management

- Centralized ordering: Single point of contact for all locations

- Department variations: Different designs by division or role

- Drop shipping: Direct delivery to multiple addresses

- Consolidated billing: Simplified accounting and invoicing

- Reorder management: Quick replication of previous orders

- Template storage: Save approved designs for future use

Production Timelines and Rush Options

Our standard production timeline of 4-6 business days meets most organizational needs while ensuring quality control at every step. For urgent situations, we offer expedited production options to meet tight deadlines.

Production Speed Options

Standard Production

Our standard 4-6 business day production timeline ensures thorough quality control and allows for complex customization options.

- 4-6 business days production time

- All materials and finishes available

- Complex customization supported

- Unlimited quantity capacity

- No rush fees

Best Value - No Rush Charges

Rush Production Options

When deadlines are critical, our rush production services deliver faster turnaround for an additional fee.

- Next-day production available (+50% rush fee)

- Same-day production for emergencies (+100% rush fee)

- Limited to orders under 100 badges

- Standard materials only for same-day

- Must be approved by 10 AM EST for same-day

Rush Fees Apply

Shipping Options (After Production)

Once production is complete, choose from multiple shipping speeds to meet your delivery requirements. Shipping times are in addition to production time.

- Standard Ground Shipping: 3-5 business days after production completion

- 2-Day Express: Guaranteed 2 business day delivery after production

- Overnight Priority: Next business day delivery after production completion

- International Shipping: Canada (3-5 days), Worldwide (5-10 days) after production

- Saturday Delivery: Available for time-critical orders

Total Timeline Examples

| Order Type |

Production Time |

Shipping Time |

Total Days |

Rush Fees |

| Standard Order + Ground |

4-6 days |

3-5 days |

7-11 days |

None |

| Standard + 2-Day Ship |

4-6 days |

2 days |

6-8 days |

Shipping only |

| Standard + Overnight |

4-6 days |

1 day |

5-7 days |

Shipping only |

| Next-Day Production + Overnight |

1 day |

1 day |

2 days |

+50% production |

| Same-Day + Overnight |

Same day |

1 day |

1-2 days |

+100% production |

Important: Rush production must be arranged in advance and confirmed by our production team. Not all materials and customization options are available for rush orders. Contact us directly for rush availability.

Why Choose NameBadge.com Over Competitors

While general print shops and office supply stores offer basic name tags, NameBadge.com specializes exclusively in professional identification solutions, delivering superior quality, durability, and service.

| Feature |

NameBadge.com |

Vistaprint |

Fastsigns |

Office Stores |

| Specialization |

Name badges only |

General printing |

Signage focus |

Office supplies |

| Material Options |

15+ options |

3-5 options |

5-7 options |

2-3 options |

| Production Time |

3-5 days standard |

7-10 days |

5-7 days |

10-14 days |

| Rush Available |

Same-day option |

3-day minimum |

2-day minimum |

Limited |

| Durability |

10+ years |

3-5 years |

5-7 years |

1-3 years |

| Bulk Discounts |

Up to 30% off |

Up to 20% off |

Up to 15% off |

Limited |

| Account Management |

Dedicated support |

Self-service |

Sales team |

None |

| Industry Expertise |

Badge specialist |

Generalist |

Signage focus |

Generalist |

Customer Success Stories

- Healthcare system: 5,000 antimicrobial badges delivered to 12 hospitals in 5 days

- Tech conference: 2,500 RFID-enabled badges with same-day design changes

- Retail chain: Ongoing monthly orders for 500+ locations nationwide

- Government agency: Security-compliant badges with holographic features

- University: 10,000 student/staff badges with role differentiation

Attachment and Fastener Manufacturing

The fastener system significantly impacts badge usability and longevity. Modern manufacturing offers solutions for every wearing preference and uniform type.

Magnetic Fastener Innovation

Advanced rare-earth magnets provide secure attachment without clothing damage, revolutionizing badge comfort and convenience.

- Triple-magnet systems: Holds through thick fabrics

- Protective coating: Prevents rust and clothing marks

- Safety designs: Rounded edges and enclosed magnets

- Quick release: Easy removal without tugging

- Universal compatibility: Works with any fabric type

Alternative Fastener Options

- Bulldog clips: Versatile attachment for various materials

- Alligator clips: Strong grip for active environments

- Swivel clips: Rotates to prevent badge flipping

- Lanyard slots: Compatible with neck wear systems

- Adhesive backing: Temporary attachment for events

- Pocket clips: Slides over pocket edges

Industry-Specific Manufacturing Solutions

Different industries require specialized manufacturing approaches to meet unique operational requirements and regulatory standards.

Healthcare Badge Manufacturing

- Antimicrobial coatings: Reduce bacterial growth on badge surfaces

- Chemical resistance: Withstands sanitizers and cleaning agents

- Role identification: Color coding for departments and positions

- Credential display: Space for certifications and titles

- Breakaway options: Safety features for patient interaction

Hospitality and Service Industries

- Elegant finishes: Match upscale environment aesthetics

- Multi-language options: Names in multiple scripts

- Seasonal designs: Holiday or event-specific badges

- Wear resistance: Maintains appearance through active service

- Brand consistency: Exact color and logo matching

Manufacturing and Industrial

- High-visibility colors: Safety-conscious design

- Heavy-duty materials: Survives harsh environments

- PPE compatibility: Works with safety equipment

- Chemical resistance: Withstands industrial exposures

- Barcode integration: Scanning for time and access

Manufacturing Timeline and Process

Understanding the production timeline helps organizations plan effectively and avoid rush charges.

Standard Production Timeline

Day 1: Design Approval

Submit design and approve digital proof. Our team reviews files and confirms production specifications.

Day 2-3: Material Preparation

Materials selected, cut to size, and prepared for printing or engraving process.

Day 3-4: Production

Printing, engraving, or etching completed. Multi-step processes for complex designs.

Day 4-5: Finishing

Assembly, quality control, and packaging for shipment.

Day 5: Shipping

Orders ship via selected method. Tracking provided for all shipments.

Factors Affecting Timeline

- Order complexity: Custom shapes and special materials may add 1-2 days

- Quantity: Large orders may require additional production time

- Proof approval speed: Delays in approval push back production start

- Material availability: Specialty materials may require ordering

- Seasonal demand: Holiday periods may extend timelines

Cost Factors in Name Badge Manufacturing

Understanding cost drivers helps organizations budget effectively and identify opportunities for savings without sacrificing quality.

Primary Cost Components

- Material selection: Plastic ($5-15), Metal ($15-35), Specialty ($10-25)

- Production method: Digital printing (lowest), Engraving (medium), Etching (highest)

- Customization level: Standard shapes vs. custom die-cuts

- Order quantity: Volume discounts available at 25, 50, 100+ units

- Fastener type: Pin ($0), Magnetic ($2-3), Specialty ($1-5)

- Rush production: 25-100% premium for expedited orders

Cost Optimization Strategies

- Bulk ordering: Combine departments for volume pricing

- Standard sizes: Common dimensions reduce material waste

- Reusable systems: Higher initial cost, lower long-term expense

- Simple designs: Minimize colors and complexity

- Planning ahead: Avoid rush fees with proper timeline

Frequently Asked Questions About Name Badge Manufacturing

What materials are available for name badge manufacturing?

Modern name badge manufacturing offers 15+ material options including eco-friendly bamboo, recycled plastics, cork, standard and premium plastics, anodized aluminum, solid brass, stainless steel, copper, bronze, and specialty materials with rhinestones or holographic effects. Each material is selected based on durability needs, environmental considerations, and brand image requirements.

How long does name badge production take?

Standard production takes 3-5 business days from design approval to shipping. Rush production with same-day turnaround is available for urgent orders. Expedited shipping options include overnight and 2-day delivery to meet tight deadlines.

Can you do bulk orders for large organizations?

Yes, we specialize in bulk orders for organizations of all sizes. Volume pricing starts at 25 units with deeper discounts at 50, 100, and 500+ badges. We handle multi-location orders, department variations, and variable data printing for personalized badges across large teams.

How does NameBadge.com compare to competitors?

NameBadge.com offers superior durability with 10+ year lifespans, USA-based manufacturing with 3-5 day production, 15+ material options including eco-friendly choices, and dedicated account management for corporate clients. Unlike general print shops, we specialize exclusively in professional identification solutions.

What customization options are available?

Full customization includes custom shapes and sizes, unlimited color options, logo integration, variable data printing for individual names and titles, department color coding, photo integration, QR codes, and special effects like holographic or thermochromic materials.

Do you offer expedited shipping?

Yes, we offer same-day production for rush orders and expedited shipping options including overnight and 2-day delivery. Rush production adds 25-100% to order cost depending on timeline. International shipping to Canada and worldwide is available.

Are there industry-specific badge solutions?

Yes, we offer specialized solutions for healthcare (antimicrobial coatings), hospitality (elegant finishes), manufacturing (chemical resistance), education (role differentiation), and security (RFID/NFC integration). Each industry solution addresses specific operational requirements.

What file formats work best for logos?

Vector files (AI, EPS, SVG) provide best quality. High-resolution PNG files at 300+ DPI or PDF files with embedded fonts also work well. Our design team can recreate logos if high-quality files aren't available.

Do you offer reusable badge systems?

Yes, reusable badge systems with permanent holders ($8-12) and replaceable paper inserts ($0.50-2) are perfect for high-turnover industries. This reduces long-term costs by up to 80% compared to ordering new permanent badges.

Can you match specific brand colors?

Yes, we offer exact Pantone color matching for brand consistency. We also work with CMYK specifications and can convert RGB colors for print production. Digital proofs ensure color accuracy before production.

Start Creating Your Perfect Name Badges Today

With manufacturing options from eco-friendly bamboo to solid metal, we create the perfect identification solution for your organization. Experience the difference of American-made quality and craftsmanship.

Explore Name Badge Manufacturing Options